Production process

ROREX pipes are produced using the continuous filament winding technology, the most technologically advanced method of GRP pipe production today. This process produces a range of diameters from 100 mm to 4000 mm.

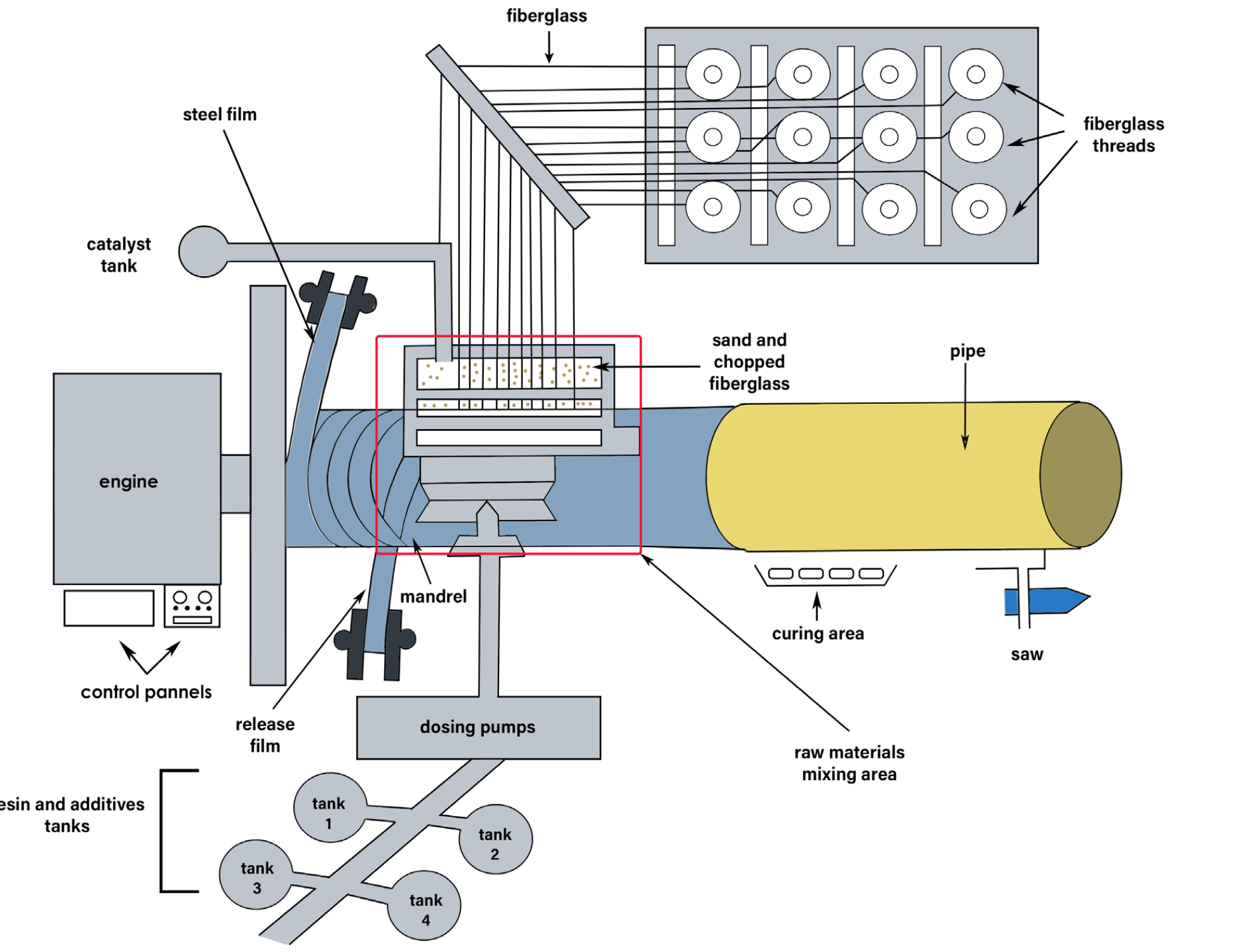

The production process consists of applying raw materials, in a certain order and in certain quantities, to the outside surface of a continuously advancing steel mandrel.

In order to protect the mould and to be able to remove the finished product from it, a release film is applied at the beginning and removed from the inside of the pipe at the end.

The basic principle of the continuous advancing mandrel process involves the use of glass fiber reinforcements in the circumferential direction of the pipe, as well as chopped rovings, which reinforce the axial direction of the pipe. These two types of reinforcement ensure the resistance of GRP pipes to both internal loads (pressure) and external loads.

Once all the raw materials have been applied, the resin polymerisation process begins, which takes place under the influence of heating, both the mandrel with an induction system and the outside of the pipe wall with an infrared radiation system. After curing the resin, the pipes are cut to the desired size.

The production process consists of applying raw materials, in a certain order and in certain quantities, to the outside surface of a continuously advancing steel mandrel.

In order to protect the mould and to be able to remove the finished product from it, a release film is applied at the beginning and removed from the inside of the pipe at the end.

The basic principle of the continuous advancing mandrel process involves the use of glass fiber reinforcements in the circumferential direction of the pipe, as well as chopped rovings, which reinforce the axial direction of the pipe. These two types of reinforcement ensure the resistance of GRP pipes to both internal loads (pressure) and external loads.

Once all the raw materials have been applied, the resin polymerisation process begins, which takes place under the influence of heating, both the mandrel with an induction system and the outside of the pipe wall with an infrared radiation system. After curing the resin, the pipes are cut to the desired size.

ROREX pipelines are designed to meet multiple international performance standards: EN (developed by the European Commission for Standardization), ISO (developed by the International Organization for Standardization), ASTM (developed by the American Society for Testing Materials), AWWA (developed by the American Water Works Association), ASME (American Society of Mechanical Engineers).