GRP pipes

Depending on the axial force to which they will be subjected and/or the installation method, ROREX can produce four types of pipes: uniaxial, biaxial, sandless and jacking pipes.

Uniaxial pipes (standard)

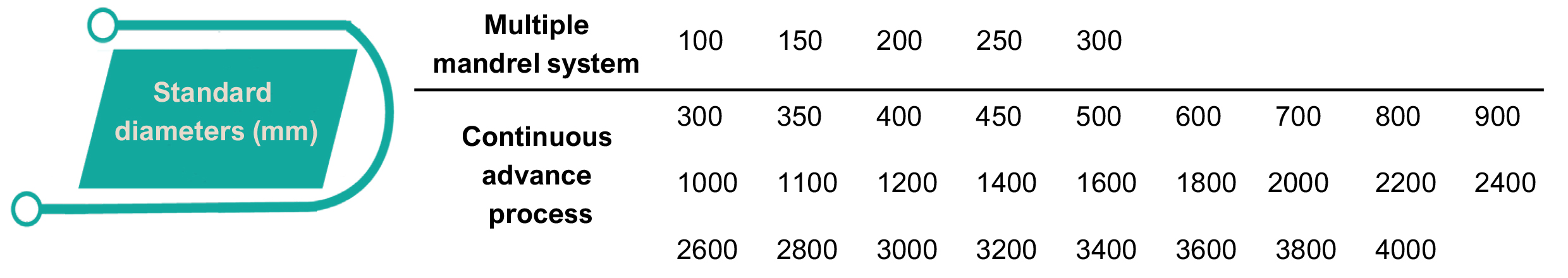

ROREX can produce on request pipes in the length range 0.3 – 15 m for diameters greater than 300 mm. Other intermediate diameters between 100 mm – 4000 mm are available on request.

Additional information on pipe properties, tests for quality control of finished pipes or considerations for design and proper operation can be found in the ROREX General Presentation Catalogue in the “Downloads” menu.

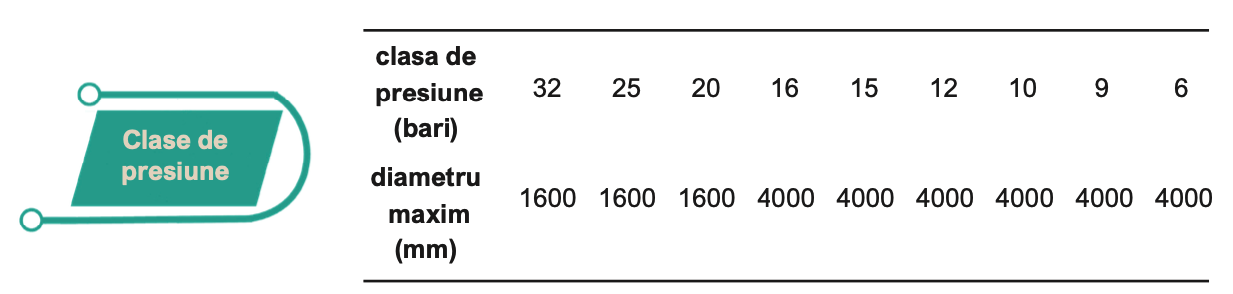

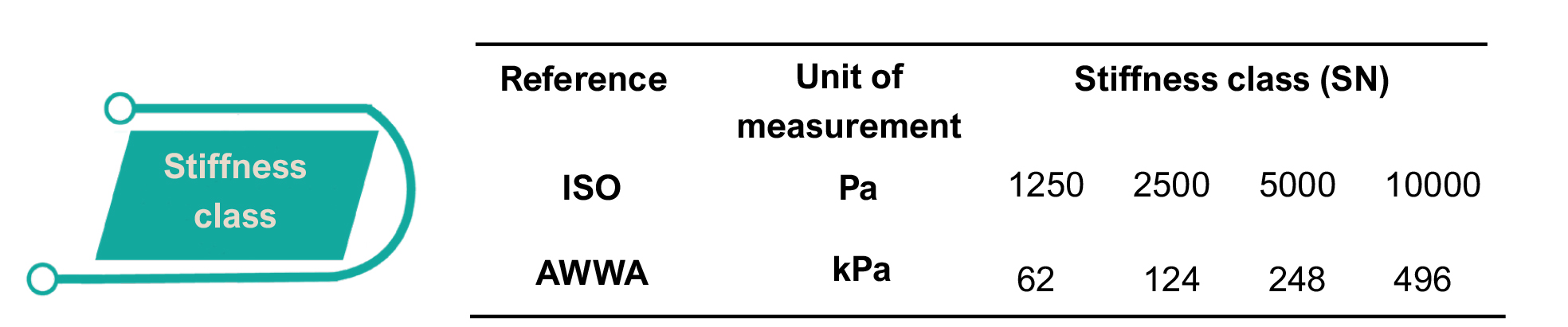

The most important parameters to take into account for the installation of underground pipes are stiffness and pressure class. The maximum burial depth is determined by a complex static calculation which takes into account the geotechnical and hydrogeological characteristics of the natural terrain, the nature and degree of compaction of the backfill material and the stiffness class of the pipeline.

To ensure good and long-lasting performance, ROREX GRP/PAFSIN pipes require proper handling and installation. The recommended installation conditions must be observed, as well as the use of an appropriate filler and backing material.

Further information on the installation of underground pipelines can be found in the ROREX Installation Manual under the “Downloads” menu. For full installation instructions, please consult the ROREX Technical Department.

They have physical, mechanical and chemical characteristics far superior to those of pipes that contain sand and are used in special applications or when the working pressure is very high. Compared to standard pipes, no-sand pipes have:

- Superior impact resistance, much better resistance to impact during handling and installation.

- Longer service life due to increased long-term performance properties of the pipes.

- Lower risk of manufacturing defects because the production process has one less parameter to control

- Lower hydraulic losses for the same nominal diameter

Further details on the physical properties of no-sand can be found in the ROREX General Presentation Catalogue in the “Downloads” menu.

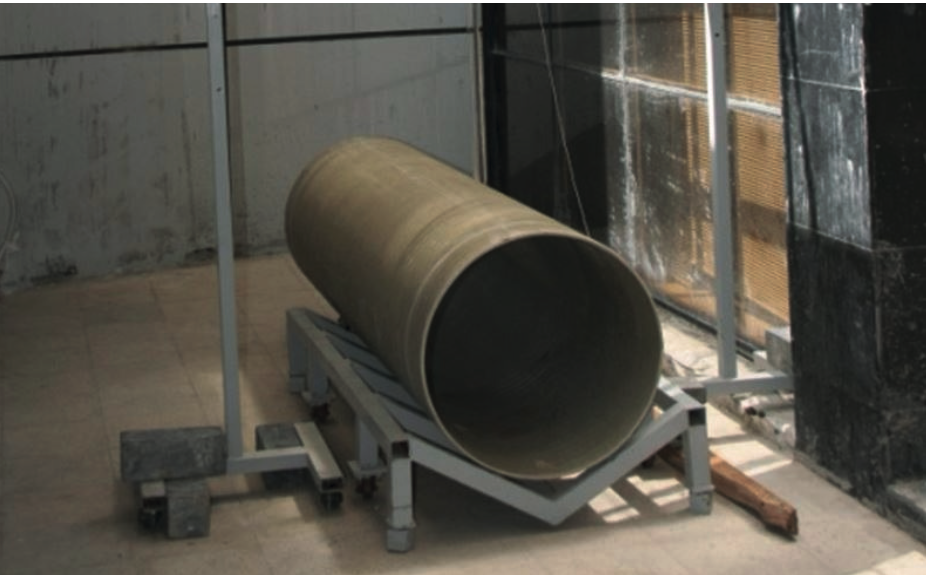

Jacking pipes

Pipe jacking pipes are made to withstand a high pushing force (700 -1000 tons) over long distances (30 – 100 m). This requires a much thicker wall than standard uniaxial pipes. In general, their length is max. 3 m so that they can be easily manoeuvrable throughout the process, especially in the vertical shaft leading to the work base.